Reliability Delivered. Capacity Proven.

When failure is not an option, Vermati provides precision machining, certified fabrication, and complex rebuilds — with audit-ready proof every time.

Start a ProjectWhat We Deliver

CNC Machining & Precision Parts

CNC capacity up to 12 tons. Reverse engineering, precision grinding, engine blocks, crankshafts, and complex geometries — delivered with QA reports.

Structural Fabrication & Welding

Steel structures, crane and gantry repairs, bridges, pressure piping, and boiler work. Certified welders following WPS/PQR procedures with inspection logs.

Pressure Vessels & Piping

ASME, API, and NBIC-compliant design, fabrication, and repair of tanks, skids, and piping systems. Hydrostatic and pressure testing with certification packages.

Component Rebuilds

Engines, transmissions, gearboxes, pumps, motors, drilling tools, and hydraulic cylinders. Full teardown, inspection, rebuild, and certified release documentation.

Surface Treatments & Coatings

Industrial blasting, protective paints, thermal spray, hard chrome plating, corrosion-resistant coatings. Delivered under SSPC/NACE standards with adhesion and thickness reports.

Laboratory & Testing Services

Oil, fuel, coolant, and metallurgical analysis for contamination, wear, and predictive maintenance. PMI, NDT, and failure analysis with certified reports.

More Services

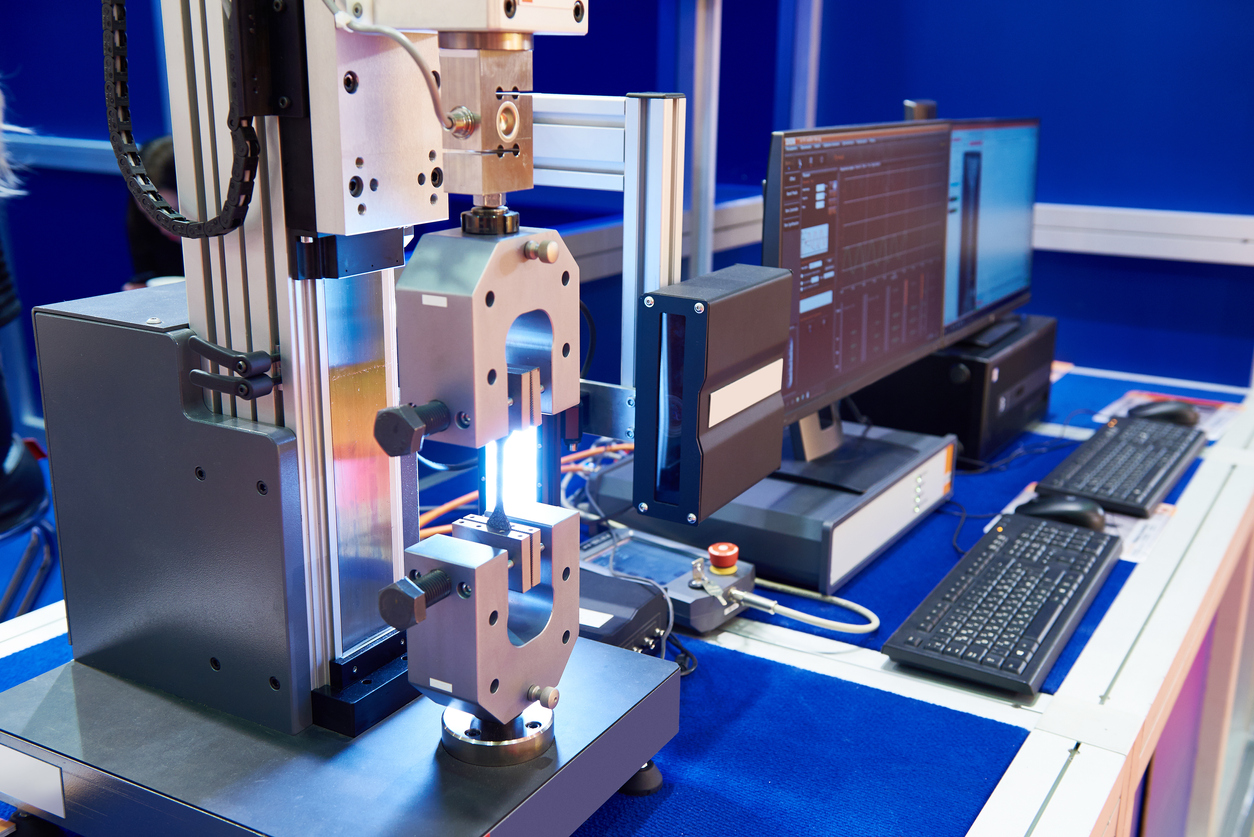

Metrology & Calibration

FARO 3D scanning, laser alignment, and gauge/tool calibration with traceable certificates.

CAD & CAE Engineering

2D and 3D CAD modeling, scanning, drafting, FEA, CFD, and design optimization.

Field Services & Supervision

On-site inspection, fit-up, commissioning, and 24/7 emergency mobilization for critical failures.

Industries Served

Ports & Maritime

Cranes, gantries, winches, vessel components, corrosion protection.

Utilities & Water

Pumps, piping, pressure vessels, and protective coatings for water and power plants.

Construction & Civil Works

Bridges, airports, steel structures, and heavy weldments.

Materials & Cement

Quarry equipment, conveyors, mills, rebuilds, and wear parts.

Oil, Gas & Energy

Skids, exchangers, vessels, piping — certified fabrication and repair.

Aviation Ground Support

Loaders, lifts, fixtures, and specialized precision machining.

Additional Sectors

Defense & Government

Certified rebuilds, heavy fabrication, and rapid-response maintenance under U.S. contracts.

Mining & Resources

Equipment rebuilds, wear parts, and specialized fabrication for mining operations.

Waste Management

Specialized equipment, structural components, and maintenance services.

How We Work

Request a Quote (24–48h)

Send drawings, specs, or photos. Vermati provides a detailed estimate fast.

Miami Contract

All contracts and invoices under U.S. law, in USD.

Execution by Experts

Certified facilities, traceable processes, and QA at every step.

Quality Package

Delivered with material certificates, weld/NDT reports, hydro test logs, coating QA, calibration certs, and lab analysis.

Delivery & Support

Managed logistics, on-site supervision, and emergency mobilization when needed.

Our Engineering Process

At Vermati, we treat engineering as a discipline, not a commodity. Every project is managed with U.S. accountability, executed in certified facilities, and delivered with the documentation and traceability our clients demand. The result: solutions that perform in the field and pass the toughest audits.

How We Work:

Certified Facilities & Processes — Every weld, vessel, and component is fabricated under ASME, API, ASTM, and NBIC standards.

Audit-Ready Documentation — Clients receive ITPs, weld maps, MRBs, NDT reports, hydrostatic charts, calibration certificates, and photographic records — bundled as a complete QA package.

Proven Expertise — Our team includes certified welders, Level II NDT inspectors, CAD/CAE specialists, and metrology experts working to exacting tolerances.

Reliability Under Pressure — From emergency spool fabrication to complex rebuilds, Vermati mobilizes quickly, delivering quality without delays.

Continuous Improvement — Each project builds on lessons learned, driving efficiency, safety, and long-term reliability.

Contact Us TodayStandards & Certifications

ASME, API, ASTM, NBIC

Compliance for vessels, piping, and heavy fabrication.

National Board "R" Stamp

Certified for pressure vessel repairs and modifications.

ISO-Grade Quality Management

Full QA/QC framework with ITPs and MRBs.

Certified Welding (WPS/PQR)

Qualified procedures with mechanical test records.

Non-Destructive Testing (NDT)

Ultrasonic, magnetic particle, and dye penetrant by Level II inspectors.

Hydrostatic & Pressure Testing

Certified results with photographic evidence.

Start your project with Vermati today

From certified fabrication to urgent rebuilds and long-term maintenance, Vermati delivers reliability on time, every time.

Request a Quote Now